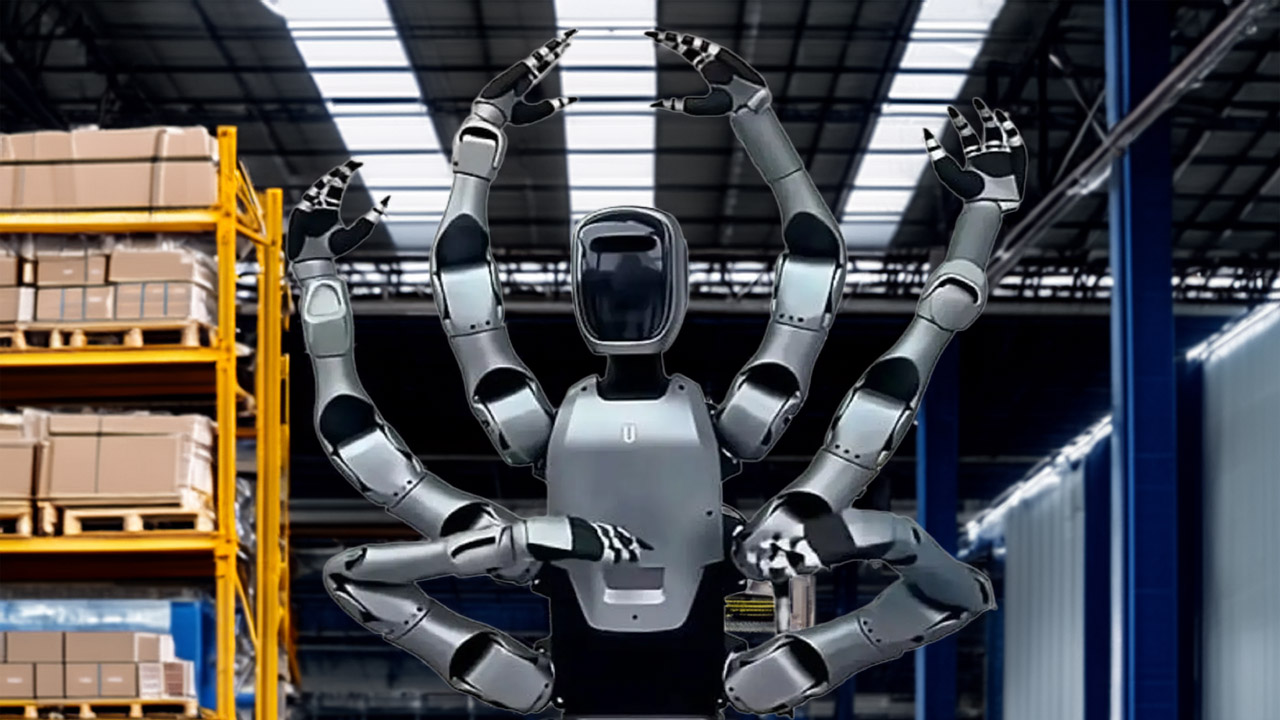

Midea’s Six-Armed Robot Factory Worker Arrives, Called MIRO U

Midea Group, well-known for its air conditioners and washing machines, has just entered the high-end robots market. On December 5, 2025, at the Greater Bay Area New Economy Forum in Guangzhou, the company created a splash by introducing MIRO U. This item piqued people’s interest; it has six arms connected to a single human-like body seated on a wheeled platform. During the demos, as the arms sprang out in this fairly beautiful synchronized position, it’s safe to say that some people couldn’t help but imagine Doctor Strange summoning extra limbs for a fight.

MIRO U is Midea’s third generation of industrial robots. The prior machines have already been silently working at the company’s plants, such as a washing machine factory in Jingzhou, where they have been lugging goods and inspecting parts. But this new one takes things to the next level, providing a ton of capacity with those extra arms.

Unitree G1 Humanoid Robot(No Secondary Development)

- Height, width and thickness (standing): 1270x450x200mm Height, width and thickness (folded): 690x450x300mm Weight with battery: approx. 35kg

- Total freedom (joint motor): 23 Freedom of one leg: 6 Waist Freedom: 1 Freedom of one arm: 5

- Maximum knee torque: 90N.m Maximum arm load: 2kg Calf + thigh length: 0.6m Arm arm span: approx. 0.45m Extra large joint movement space Lumbar Z-axis…

Each arm is a full bionic limb, built for extremely precise movement. Engineers incorporated high-precision control systems into them, and the end effectors can be swapped out in seconds, allowing the robot to easily transition from screwing parts together to lifting large heavy objects. The lower arms undertake the heavy lifting, while the upper arms focus on delicate assembly work.

Mobility is provided by a heavy-duty wheeled chassis, also known as wheel-leg for stability. The base allows for vertical lifting to alter the height of different workstations. Full 360-degree rotation on the spot allows the robot to spin swiftly without repositioning its wheels. Because the torso and head are at typical bench heights, it is compatible with existing industrial lines designed for human workers.

Company executives prioritize efficiency over looks. Wei Chang, Midea’s vice president and chief technology officer, emphasized that MIRO U is concerned with real-world performance in industrial environments. Six arms allow for simultaneous activities, such as handling three different tasks at once. This method accelerates production line changeovers, in which workers switch setups between product runs.

By the end of December 2025, MIRO U will begin pilot testing at Midea’s high-end washing machine facility in Wuxi, Jiangsu province. According to company forecasts, if completely integrated, changeover times will improve by 30 percent. Success here could lead to more widespread deployment throughout Midea’s facilities. Midea built the complete technology stack in-house, leveraging years of investment. In 2017, the company bought industrial robot manufacturer Kuka and built specialist labs for heavy-duty machinery. Parallel efforts are underway on a distinct series dubbed Meila, which is geared at commercial and residential areas and is scheduled to be released in 2026.

[Source]

Midea’s Six-Armed Robot Factory Worker Arrives, Called MIRO U

#Mideas #SixArmed #Robot #Factory #Worker #Arrives #Called #MIRO