3D-Printed Hydrofoil Bike Pedals Above the Waves, Sort Of

Maker RCLifeOn came up with a crazy idea one day: why not remove the board from that hydrofoil setup and replace it with something with pedals and gears? The result is a contraption that promises to glide over the water on plastic and wood wings, driven solely by the rider’s own two legs and the gentle hum of an electric engine. Months of scribbling down ideas and late-night printing sessions later, that concept finally hit the water for the first time.

RCLifeOn started the project off simply, with an airfoil form found through a quick online search. Then he used Fusion 360 software to trace and extrude the curve into a 3D shape before sending it to his printer. Low infill restricted the weight to roughly 200g, preventing it from sinking completely under water. Wooden dowels threaded through the middle provided much-needed structural support, while motor wires snaked up the inside of the upright mast. A good slathering of super glue held everything together, and it proved to be stronger than the plastic itself.

Sale

Bambu Lab A1 Mini 3D Printer, Support Multi-Color 3D Printing, Set Up in 20 Mins, High Speed & Precision,…

- High-Speed Precision: Experience unparalleled speed and precision with the Bambu Lab A1 Mini 3D Printer. With an impressive acceleration of 10,000…

- Multi-Color Printing with AMS lite: Unlock your creativity with vibrant and multi-colored 3D prints. The Bambu Lab A1 Mini 3D printers make…

- Full-Auto Calibration: Say goodbye to manual calibration hassles. The A1 Mini 3D printer takes care of all the calibration processes automatically,…

The structure began to take shape from sheets of plywood, which he simply cut into standoffs to form the basic skeleton. Then he draped some 3D printed perimeter plates over the edges to make it resemble a skirt. Four rods connected the parts, allowing some space in the center for expanding foam. He utilized around 15 liters of the material, carefully matching the predicted total weight of 20kg (with batteries). That amount of foam managed to displace just enough water to keep the whole thing afloat, rider and all. On top went a seat, front handlebars, and a coat of weatherproof sealant, followed by a layer of white paint for a pleasant touch.

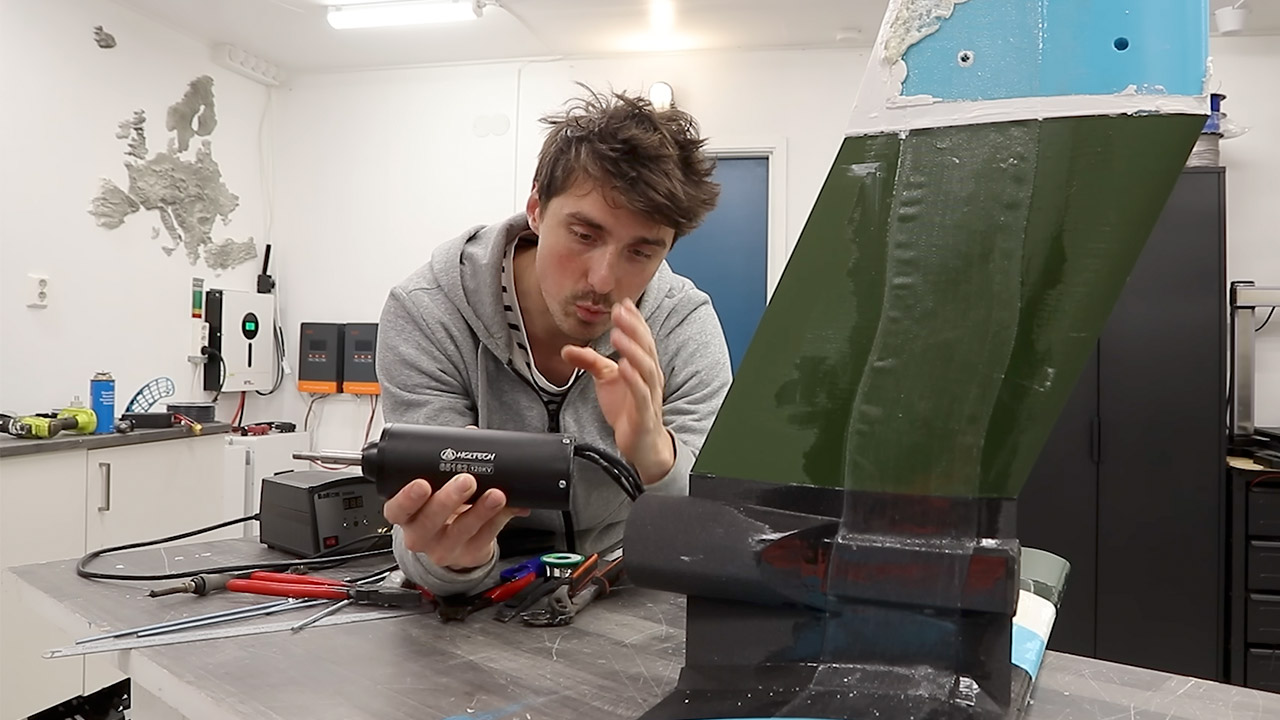

Next came some reinforcements, as previous builds had taught RCLifeOn a few painful lessons. He wrapped polyester resin and glass fiber across the connection where the mast joins the wing, which had previously snapped due to stress. Carbon fiber strips filled the gaps in the front assembly, firmly bonded into plywood tabs for a strong hold. The front foil was scaled down to 30% of the size of the main one, with holes drilled in it so he could adjust the angle and tilt to his liking. Finally, he slapped on some wing tips, a nose cone, and additional printed plastic, all in an effort to reduce drag and part the waves ahead of him.

However, electronics proved to be a much bigger challenge. A brushless motor was installed in the mast, powered by 48-volt batteries and operated by a twist throttle. The only problem was that it wasn’t performing as intended; it would spin backwards at half throttle or not at all. One problem was solved with servo testers; another was solved after a full day of tinkering with cables to locate corrosion caused by old water exposure. Soldered connections and wiring ensured that electricity flowed steadily, an inexpensive converter reduced 12 volts to 5 for the controls, and a bit of plastic prevented splashes during testing.

Launch day was one of those painful slow-motion things, as the foam caused the bike to float high, making what should have been a straightforward climb aboard into a real-life puzzle. Twenty minutes passed before he was able to straddle it from a dock, his legs straining against the float. A countdown rang before he pushed off into the current. For a brief period, everything was fine; the foils caught the flow, and he thought it would work. Then, calamity hit. He was flailing around on a shallow ledge for two minutes when a friend waded in and pushed him free. Momentum briefly increased before the front foil snapped against a hidden impediment.

Power was always a given, as that brushless motor had powered him 500 kilometers of real-world hauls while remaining whisper quiet while turning the rear tire. But when it came to water, it couldn’t seem to move swiftly enough without the foils biting through. Drag was tearing at it from every inch below the water, and without complete elevation, it was more like riding a bike through muck than planing on the water. Of course, the cold made matters worse, resulting in brittle platic hinges and numb hands from the moisture. Even though the electronics were sealed, it appeared that moisture was inviting itself in.

[Source]

3D-Printed Hydrofoil Bike Pedals Above the Waves, Sort Of

#3DPrinted #Hydrofoil #Bike #Pedals #Waves #Sort